What is Fluid-Structure Interaction and Why is it Important?

In today’s engineering world, Fluid-Structure Interaction (FSI) is a comprehensive concept that examines the interaction of fluids or gases on structures. In this article, we will focus on understanding what fluid-structure interaction is and why it is so important in engineering.

What is Fluid-Structure Interaction?

Fluid-structure interaction is an engineering discipline for understanding the effects of fluid or gas flows on a structure, as well as the effects of that fluid on the structure. In many scenarios, such as the effects of wind on bridges, the effect of water on the behaviour of ships or the aerodynamic performance of aircraft, fluid-structure interaction analyses make engineers’ design processes more effective and realistic.

Why is it Important?

- Safety and Durability: Fluid-structure interaction analyses help assess potential risks to improve the durability and safety of structures. This is an important factor, especially in infrastructure projects such as bridges, buildings and energy facilities.

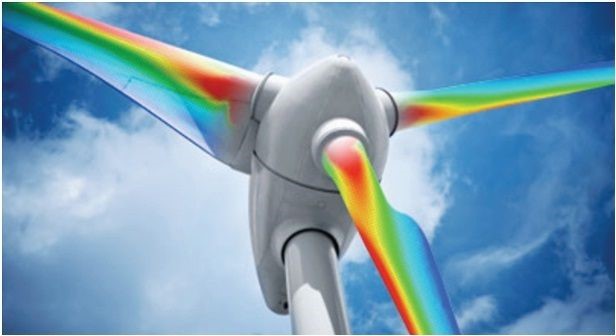

- Performance Optimisation: FSI enables performance optimisation in product or structure design. This can improve energy efficiency and overall performance in a wide range of applications, from wind turbines to aircraft wings.

- Application Diversity: Many industries such as marine, aerospace, energy sector and construction benefit from fluid-structure interaction analyses. Therefore, engineers can successfully approach a variety of projects in different application areas using this discipline.

Fluid-Structure Interaction Applications

Marine Applications: Subsea platforms, ships and marine vessels are subjected to large fluid loadings under marine conditions such as wave action, currents and wind. FSI provides solutions to improve the durability and performance of underwater structures, utilised in ship design and marine strategies. Example: By simulating how a submarine platform behaves under wave action, structural modifications can be made and maritime safety can be improved. Aviation Applications: When wings, fuselages and other structural components of aircraft are exposed to airflow, they encounter aerodynamic interactions. FSI analyses are used to optimise performance in aircraft design.The Role of ANSYS in FSI Simulation:

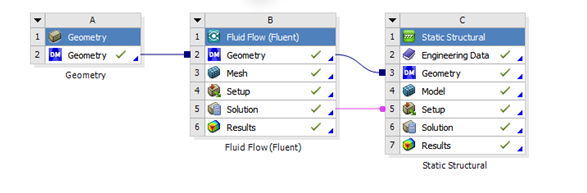

ANSYS, a widely used simulation software, provides advanced tools and capabilities for conducting FSI simulations. It offers a comprehensive suite of solvers that can accurately model and simulate fluid flow, structural mechanics and their interaction. ANSYS Fluid Dynamics solutions enable engineers to analyse complex fluid behaviour, including laminar and turbulent flow, multiphase flow and heat transfer. ANSYS Mechanical solutions enable precise structural analyses, taking into account factors such as material properties, boundary conditions and loading conditions. By combining these capabilities, ANSYS provides a robust platform for FSI simulation. When the solid begins to deform and deformations need to be accounted for, ANSYS can combine fluid and structural simulations to transfer data between solvers for one-way or two-way coupled simulation.How is One-Way FSI Simulation Performed?

A one-way FSI simulation is a type of simulation in which the fluid models its effect on the structure, but does not act back to the fluid by the structure. This is achieved through a simple drag and drop task that automatically connects the geometry and solution cells of your simulation.

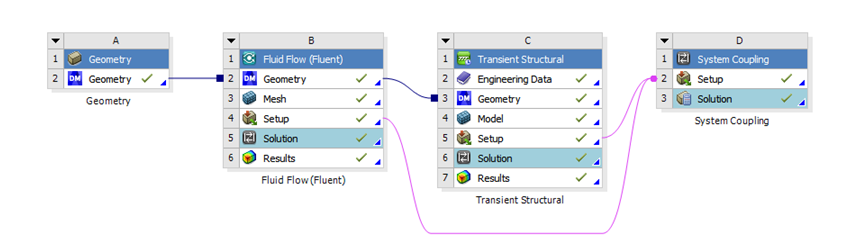

How is Bidirectional FSI Simulation Performed?

Bidirectional FSI simulation is a type of simulation in which the fluid acts on the structure and at the same time an effect is sent by the structure to the fluid. That is, mutual interaction between the fluid and the structure is taken into account. Using System Link, Fluid and Mechanical simulations can be run simultaneously with two-way data exchange throughout the simulation.